Learn more about Welding Training

Introduction to Welding Training

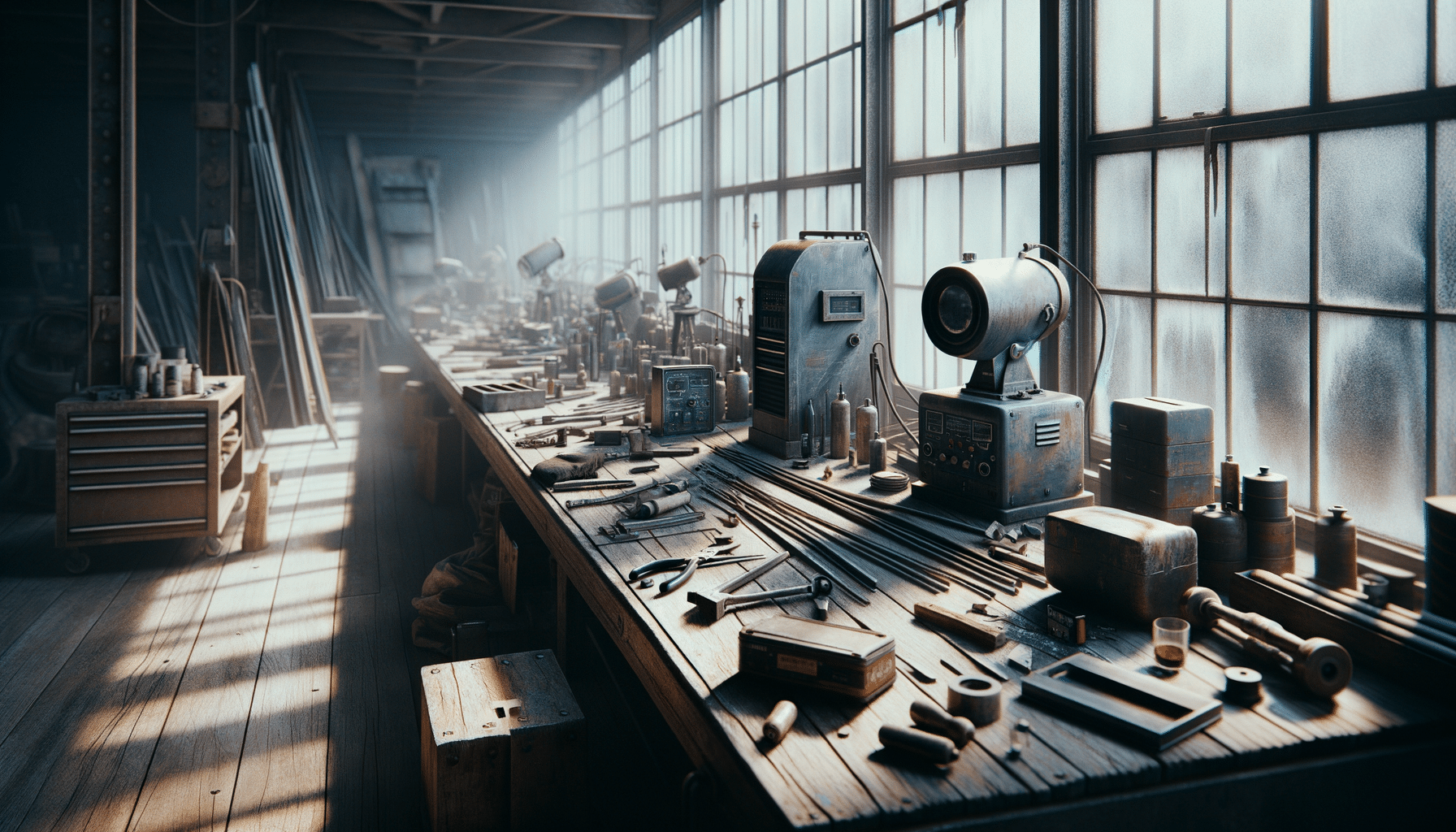

Welding is a critical skill across numerous industries, from construction to automotive, and even in art. The demand for skilled welders is consistently high, making welding training an essential stepping stone for anyone looking to enter this field. Welding training not only equips individuals with the technical know-how but also ensures they understand the vital safety protocols necessary in this potentially hazardous profession.

Welding training covers a broad spectrum of techniques and processes. It prepares individuals to handle various materials and conditions, enabling them to produce strong, durable welds. With the right training, welders can work in diverse environments, including shipyards, construction sites, and manufacturing plants. This versatility makes welding an attractive profession for those seeking job stability and variety.

Furthermore, welding training is not just about acquiring technical skills. It also instills a sense of precision and attention to detail. Welders must often work with complex blueprints and specifications, requiring a high level of accuracy and problem-solving abilities. These skills are not only valuable in welding but are transferable to other areas of work, providing a broad foundation for career advancement.

The Core Components of Welding Training

Welding training is comprehensive, covering various techniques essential for mastering the craft. The curriculum typically includes the study of different welding processes, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and stick welding. Each of these processes has its unique applications and requires specific skills and equipment.

In addition to process-specific training, welding courses often delve into material science, teaching students about the properties of different metals and how they react under heat. This knowledge is crucial for making informed decisions about welding techniques and materials, ensuring the structural integrity of the final product.

Another critical component of welding training is safety. Welding involves high temperatures, intense light, and potentially dangerous fumes. Training programs emphasize the importance of personal protective equipment (PPE) and safe working practices to prevent accidents and health issues. Understanding and implementing safety protocols is non-negotiable in the welding industry, making this aspect of training particularly vital.

- Understanding different welding processes

- Material science and metal properties

- Safety protocols and use of PPE

Career Opportunities in Welding

The career prospects for trained welders are vast and varied. Welding skills are in demand across multiple industries, providing opportunities for specialization and advancement. For instance, welders can find roles in construction, manufacturing, automotive repair, and even in aerospace, where precision welding is crucial for safety and performance.

With additional certifications and experience, welders can advance to supervisory or inspection roles. Certified Welding Inspectors (CWIs), for example, play a critical role in maintaining quality and safety standards in welding projects. This path offers a rewarding career with the potential for higher earnings and greater responsibility.

Moreover, the global demand for infrastructure development and maintenance continues to drive the need for skilled welders. As countries invest in rebuilding and expanding their infrastructure, the demand for qualified welders is expected to rise, ensuring job security and growth opportunities in the field.

- Roles in construction and manufacturing

- Specializations in automotive and aerospace welding

- Opportunities for advancement to supervisory roles

Safety in Welding: A Non-Negotiable Aspect

Safety is a cornerstone of welding training and practice. The nature of welding work, with its exposure to high heat, bright light, and hazardous fumes, necessitates stringent safety measures. Welding training programs place a significant emphasis on safety, ensuring that trainees are well-versed in the use of personal protective equipment (PPE) and understand the importance of maintaining a safe working environment.

PPE includes helmets with face shields, gloves, aprons, and protective eyewear. These items protect welders from burns, eye damage, and exposure to harmful UV rays. Beyond PPE, training also covers the safe handling of equipment and materials, as well as emergency procedures in the event of an accident.

Understanding and adhering to safety protocols is not only a legal requirement but also a professional responsibility. It ensures the well-being of the welder and their colleagues, allowing them to work efficiently and confidently. By prioritizing safety from the outset, welding training programs help cultivate a culture of safety that benefits the entire industry.

The Future of Welding Training: Embracing Technology

As technology continues to advance, welding training is evolving to incorporate new tools and techniques. The introduction of virtual reality (VR) in welding training is a notable development, offering trainees a safe and cost-effective way to practice their skills. VR simulations allow students to gain hands-on experience without the risks associated with live welding, providing an immersive learning environment that enhances their understanding and proficiency.

Additionally, automation and robotics are becoming increasingly prevalent in the welding industry. Training programs are adapting to these changes by including courses on robotic welding and automated systems. This training prepares welders for the future, equipping them with the skills needed to operate and maintain advanced welding technologies.

The integration of technology in welding training not only improves the learning experience but also ensures that welders remain competitive in a rapidly changing industry. By embracing these innovations, welding training programs are setting the stage for a new generation of skilled, tech-savvy welders ready to meet the demands of modern industry.

- Incorporation of VR in training

- Training in robotic and automated welding systems

- Preparing for a tech-driven future in welding